Alternative Designs of the MS21042 Series

Due to the popularity of MS21042 lock-nuts in the aerospace industry there is a high demand for an alternative lock-nut that is less susceptible to failure.

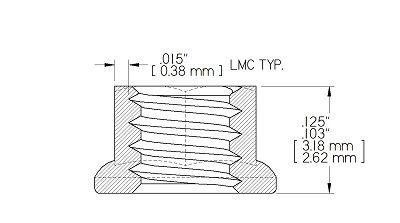

One of the main criticisms of the MS21042 design is its thin wall design. As a result of this thin wall design, manufacturers must heat treat the nut to high Rockwell hardness to meet the tensile requirements of the standard. However, high hardness requirements make the material more susceptible to cracking and induced hydrogen embrittlement.

Alternative designs, that increase the wall thickness of the MS21042 nut, allow for lower hardness values to meet the tensile requirements of the standard.

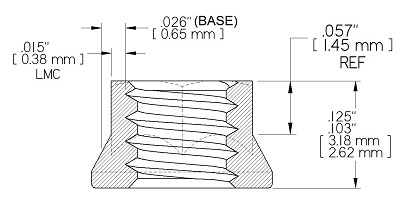

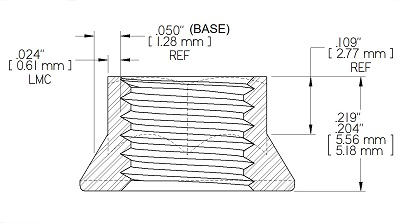

MS21042 Bell Flange Design 'Style B'

MS21042.info was recently contacted by the engineering firm Inspec100 with a patented bell flange design of the MS21042 nut known as 'Style B'.

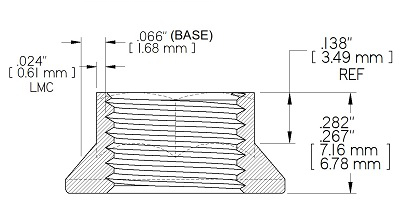

The advantages of this new design is that it increases the wall thickness around the base of the MS21042 nut. It is widely accepted that 80% of the load is carried by the first two threads in conventionally threaded fasteners. As a result this increase of wall thickness around the base two threads makes for a much stronger design that can be heat treated to lower values to meet the tensile requirements.

The primary advantages of this design is that it is dimensionally within the specifications of the NASM21042 standard. As such, this 'Bell Flange Design' can be used without redesign of the application, or the use of 12-point tools for installation.

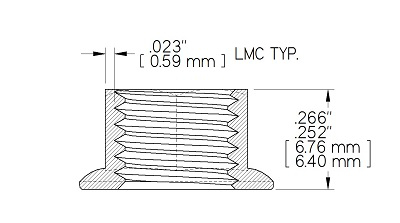

The combined drawings of the style A and B nut can be found below for comparison:

The images and illustrations used here within are used with the permission of Inspec100. For more information on the MS21042 'Style B' design please visit www.inspec100.com/MS21042B.html